As part of the H&M productivity program, GTE conducted training and on-site inspections for 20 different H&M supplier textile companies across Turkey (Tekirdağ, Kırklareli, Istanbul, Malatya, Kahramanmaraş, Bursa, Denizli, İzmir) in 2018. During the facility visit of textile manufacturers, water, chemical, dye, and energy saving opportunities were investigated and reports containing recommendations were prepared for each facility.

In 2019, GTE monitoring studies were carried out during the implementation phase of manufacturers’ related resource and eco-efficiency opportunities. Within the scope of monitoring, a repeat visit was made to the facilities and developments were evaluated.

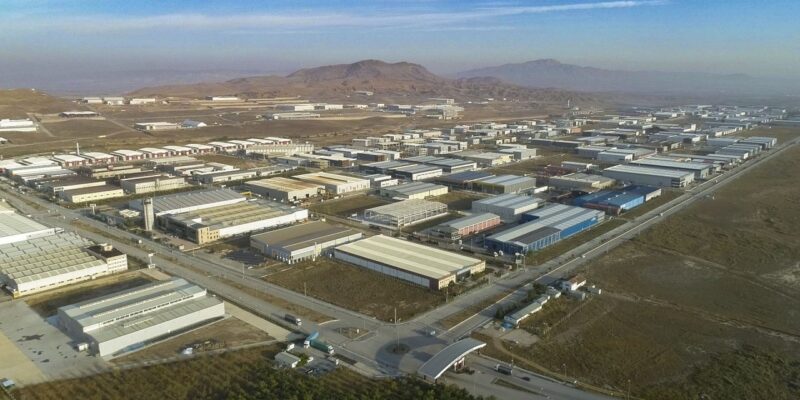

Another project we have done with H&M: